In the world of packaging, choosing the right printing technique can make a significant difference in the overall appeal and effectiveness of a product. With numerous options available, it can be challenging to determine the best type of printing for packaging. In this article, we will explore various printing techniques and their suitability for different packaging needs, ensuring that your products stand out in the competitive market.

- Flexographic Printing:

Flexographic printing, also known as flexo printing, is a widely used technique for packaging. It involves the use of flexible relief plates and fast-drying inks. This method is particularly suitable for large-scale production, as it offers high-speed printing capabilities and excellent color reproduction. Flexographic printing is commonly used for corrugated boxes, labels, and flexible packaging materials. - Offset Lithography:

Offset lithography, often referred to as litho printing, is a popular choice for high-quality packaging. This technique utilizes metal plates and rubber blankets to transfer the image onto the packaging material. Offset lithography offers precise color reproduction, sharp details, and consistent results. It is commonly used for folding cartons, paperboard packaging, and promotional materials. - Digital Printing:

Digital printing has revolutionized the packaging industry with its flexibility and cost-effectiveness. This technique involves directly printing the artwork onto the packaging material using digital files. Digital printing offers quick turnaround times, customization options, and the ability to print variable data. It is ideal for short runs, personalized packaging, and prototypes. - Gravure Printing:

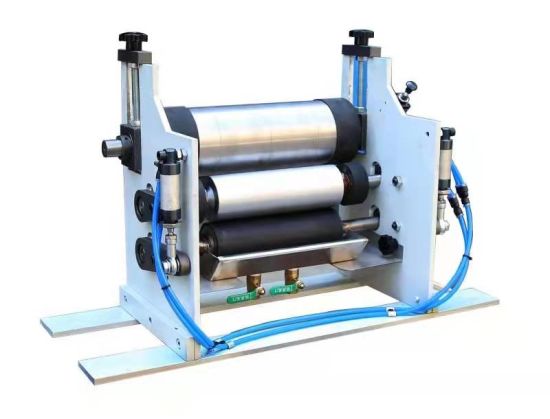

Gravure printing, also known as rotogravure printing, is a high-quality and versatile printing technique. It utilizes engraved cylinders to transfer ink onto the packaging material. Gravure printing excels in reproducing intricate designs, vibrant colors, and fine details. It is commonly used for flexible packaging, labels, and high-end consumer goods. - Screen Printing:

Screen printing, also called silk screen printing, is a versatile technique suitable for various packaging materials. It involves pushing ink through a mesh screen onto the packaging surface. Screen printing offers vibrant colors, excellent opacity, and the ability to print on uneven surfaces. It is commonly used for bottles, jars, and promotional items.

Conclusion:

Selecting the best type of printing for packaging depends on several factors, including the desired outcome, budget, and production volume. Flexographic printing is ideal for large-scale production, while offset lithography offers high-quality results. Digital printing provides customization options, and gravure printing excels in intricate designs. Screen printing is versatile and suitable for various packaging materials. By understanding the strengths and applications of each printing technique, you can make an informed decision and elevate your packaging to new heights.