In the realm of motor control, relays play a pivotal role in ensuring efficient and safe operation of various industrial applications. A relay is an electromechanical device that acts as a switch, allowing or interrupting the flow of electrical current to control the operation of motors. This article delves into the intricacies of relays in motor control, exploring their functionality, types, and applications.

- Understanding the Functionality of Relays:

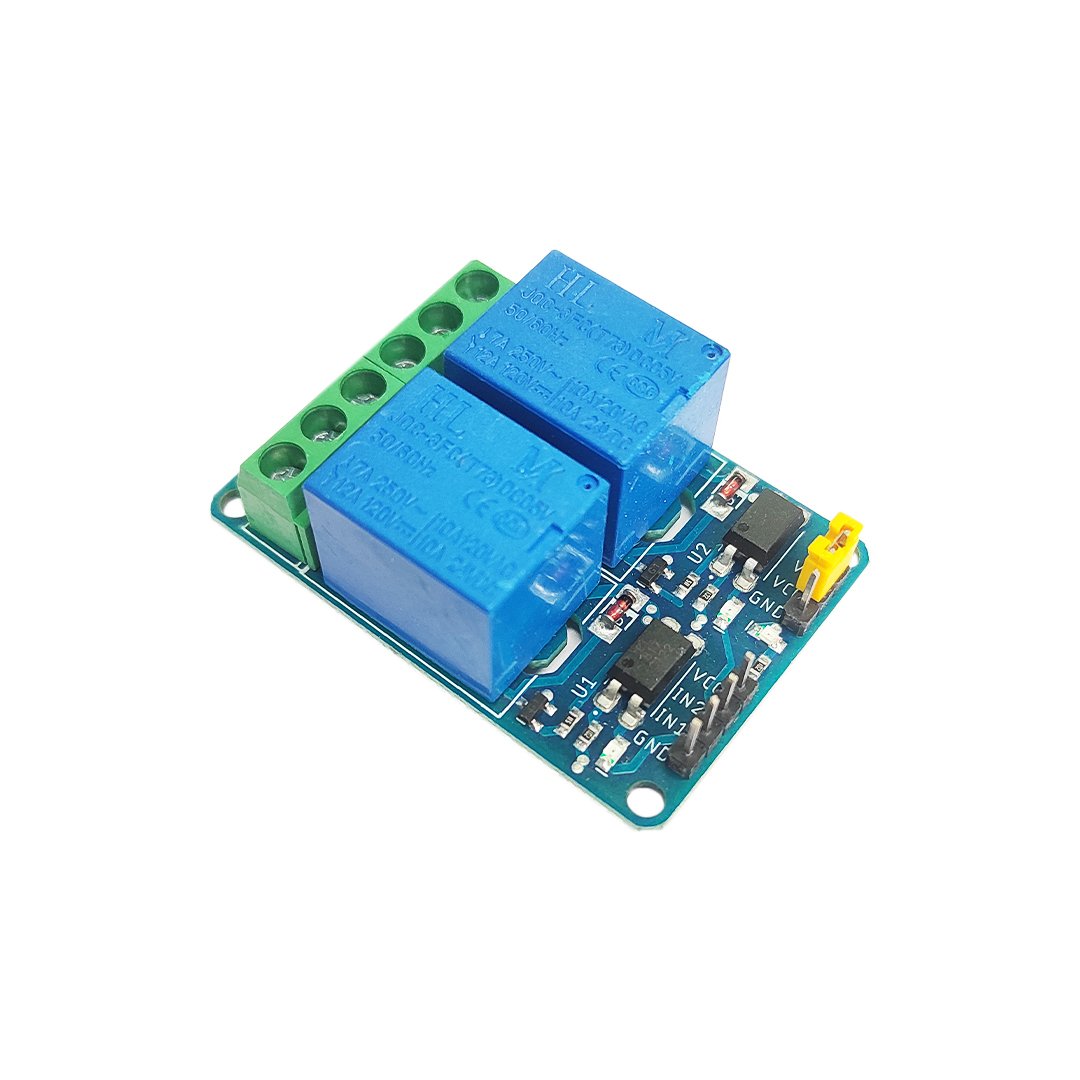

Relays serve as an interface between low-power control circuits and high-power motor circuits. They are designed to handle large currents and voltages, providing a reliable means of controlling motors. When a control signal is received, the relay's coil energizes, causing the contacts to close or open, thereby allowing or interrupting the current flow to the motor. This mechanism ensures that the motor operates as intended, preventing damage and enhancing overall efficiency. - Types of Relays in Motor Control:

a. Electromechanical Relays: These relays utilize an electromagnetic coil to control the switching action. They are commonly used in applications where high switching speeds and long-term reliability are required. Electromechanical relays offer excellent isolation between the control circuit and the motor circuit, ensuring enhanced safety.

b. Solid-State Relays (SSRs): SSRs employ semiconductor devices such as thyristors or triacs to perform the switching operation. They offer advantages such as faster response times, reduced power consumption, and improved durability compared to electromechanical relays. SSRs are particularly suitable for applications requiring frequent switching or where noise reduction is crucial.

c. Thermal Overload Relays: These relays are specifically designed to protect motors from overheating. They monitor the motor's current and temperature, and in the event of an abnormal rise in either parameter, they trip to interrupt the power supply. Thermal overload relays prevent motor burnout and extend its lifespan, making them indispensable in motor control systems.

- Applications of Relays in Motor Control:

a. Industrial Automation: Relays are extensively used in industrial automation systems to control motors in manufacturing processes. They enable precise control over motor speed, direction, and torque, facilitating efficient production and reducing downtime.

b. HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems rely on relays to control the operation of motors driving fans, compressors, and pumps. Relays ensure optimal temperature regulation, energy efficiency, and fault protection in HVAC applications.

c. Electric Vehicles: Relays are crucial components in electric vehicle (EV) motor control systems. They enable seamless switching between various motor modes, such as acceleration, deceleration, and regenerative braking, ensuring smooth and efficient operation of EVs.

Conclusion:

Relays play a vital role in motor control, enhancing efficiency and safety in a wide range of industrial applications. By providing reliable switching functionality, relays enable precise control over motors, preventing damage and optimizing performance. Understanding the different types of relays and their applications empowers engineers and technicians to design robust motor control systems that meet the demands of modern industries.