Testing electronic circuits is a critical process in the design and manufacturing of electronic devices. It ensures that circuits function as intended, meet specifications, and maintain reliability over time. In this article, we will delve into the methodologies, tools, and best practices for effectively testing electronic circuits, providing engineers with a robust framework to enhance their testing processes.

Understanding the Importance of Circuit Testing

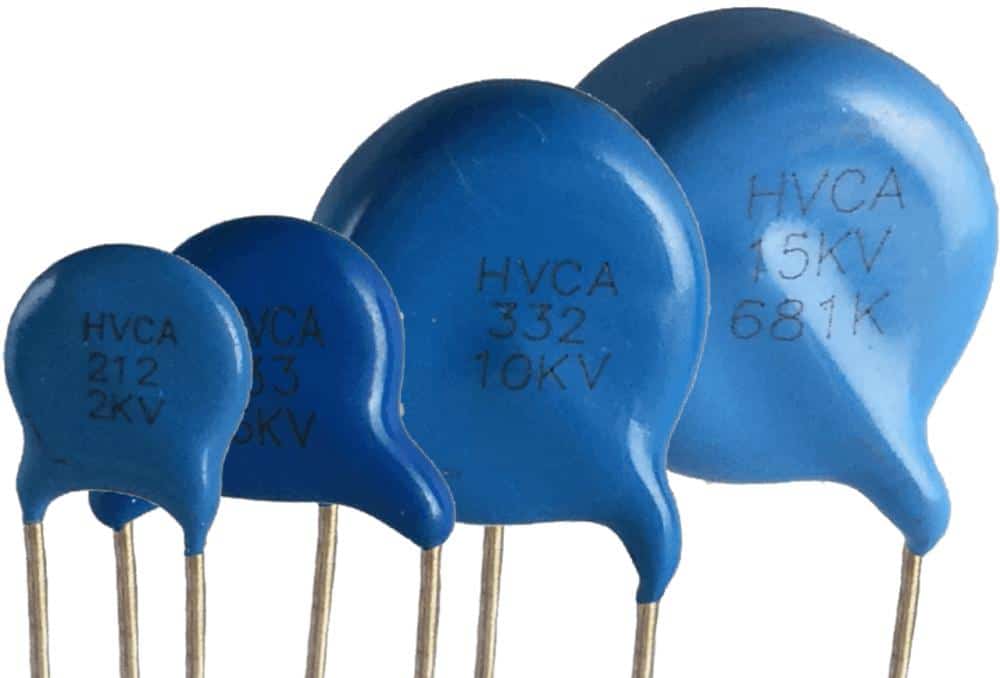

Before we explore the testing methods, it’s essential to understand why testing is crucial. Electronic circuits can be complex, comprising various components such as resistors, capacitors, diodes, and integrated circuits. Each component must work harmoniously to ensure the overall functionality of the circuit. Testing helps identify issues such as:

- Design Flaws: Early detection of design errors can save time and resources.

- Component Failures: Identifying faulty components before mass production prevents costly recalls.

- Performance Verification: Ensuring that the circuit meets performance specifications under various conditions.

Types of Testing Methods

There are several methods to test electronic circuits, each suited for different stages of the design and manufacturing process. Here are the most common approaches:

- Visual Inspection

Visual inspection is often the first step in the testing process. Engineers examine the circuit board for obvious defects such as soldering issues, misplaced components, or physical damage. This method is quick and can catch many problems before more sophisticated testing begins.

- Functional Testing

Functional testing involves verifying that the circuit performs its intended functions. This can be done using:

- Test Equipment: Devices such as oscilloscopes, multimeters, and signal generators can be employed to measure voltage, current, and signal integrity.

- Test Scripts: Automated test scripts can be developed to run through various scenarios, ensuring that the circuit behaves as expected under different conditions.

- In-Circuit Testing (ICT)

In-circuit testing is a more advanced method that checks the functionality of individual components while they are still mounted on the circuit board. This method uses specialized test fixtures and probes to measure parameters such as resistance, capacitance, and inductance. ICT is particularly useful for identifying faulty components without the need for complete disassembly.

- Boundary Scan Testing

Boundary scan testing is a technique used primarily for digital circuits. It utilizes a standardized test access port (TAP) to control and observe the state of digital signals at the boundary of integrated circuits. This method is invaluable for testing complex circuits where physical access to pins is limited.

- Environmental Testing

Environmental testing assesses how circuits perform under extreme conditions, such as temperature fluctuations, humidity, and vibration. This type of testing is crucial for applications in aerospace, automotive, and industrial sectors, where reliability is paramount.

Best Practices for Effective Circuit Testing

To maximize the effectiveness of your testing processes, consider the following best practices:

- Develop a Comprehensive Test Plan

A well-structured test plan outlines the objectives, methods, and criteria for success. It should include:

- Test Objectives: Define what you aim to achieve with each test.

- Test Environment: Specify the conditions under which testing will occur.

- Documentation: Keep detailed records of test procedures, results, and any anomalies.

- Utilize Automated Testing

Automation can significantly enhance testing efficiency and accuracy. Automated test equipment (ATE) can execute complex test sequences quickly and consistently, reducing human error and freeing engineers to focus on analysis and troubleshooting.

- Incorporate Simulation Tools

Before physical testing, use simulation software to model circuit behavior. Tools like SPICE (Simulation Program with Integrated Circuit Emphasis) allow engineers to predict how circuits will perform under various conditions, identifying potential issues early in the design phase.

- Iterate and Refine

Testing should be an iterative process. After identifying issues, refine the circuit design and retest. This cycle of testing and refinement is crucial for achieving optimal performance and reliability.

Conclusion

Testing electronic circuits is an indispensable part of the engineering process that ensures functionality, reliability, and performance. By employing a combination of visual inspection, functional testing, in-circuit testing, boundary scan testing, and environmental testing, engineers can effectively identify and rectify issues. Adopting best practices such as developing comprehensive test plans, utilizing automation, incorporating simulation tools, and iterating designs will further enhance the testing process. As technology continues to evolve, staying abreast of the latest testing methodologies and tools will empower engineers to deliver high-quality electronic products that meet the demands of an increasingly complex market.