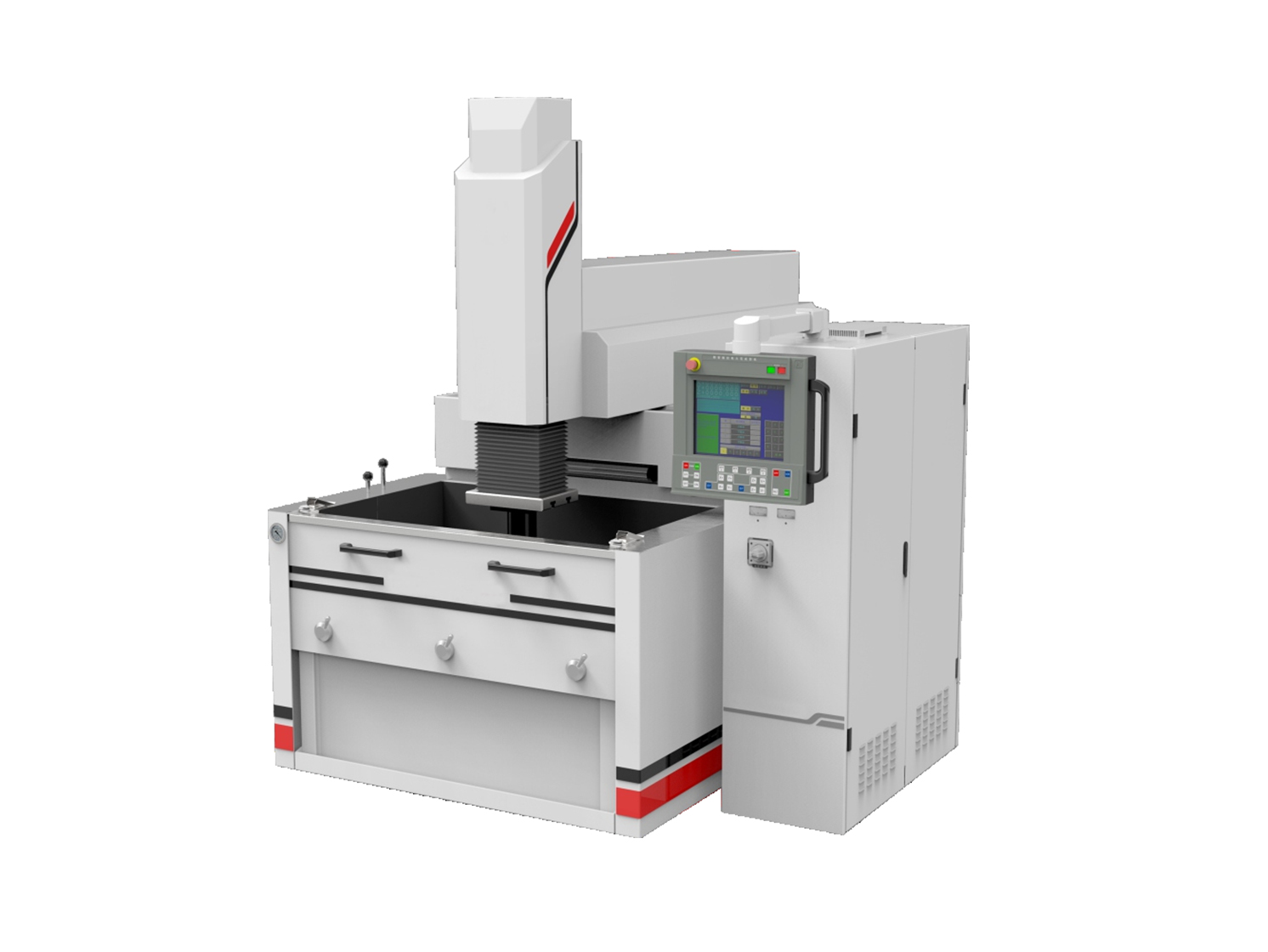

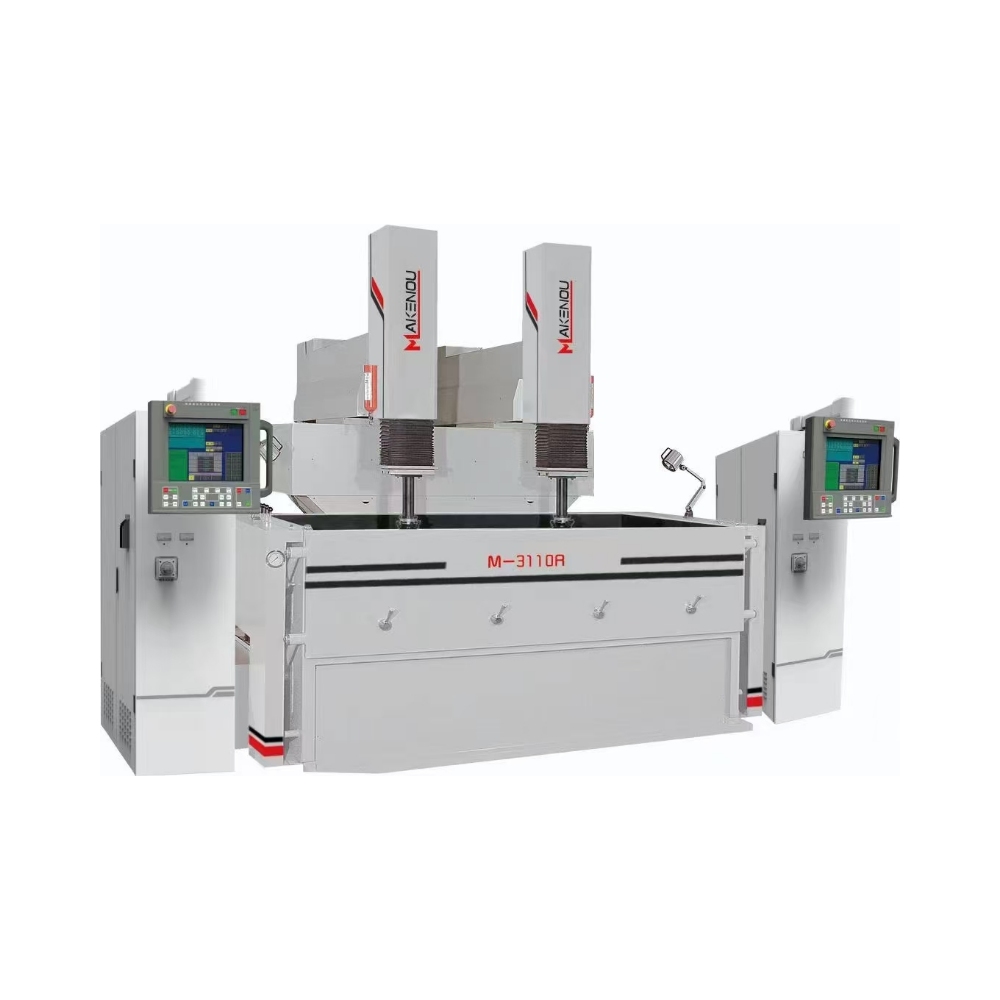

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. offers advanced EDM machines that deliver reliable, high-precision machining — tools that excel in demanding industries requiring complex shapes, tight tolerances, and consistent surface quality.

Below we explore the versatile and high-value applications of EDM (Electrical Discharge Machining) machines, highlighting how their unique strengths — and machines from Zhiquan — serve diverse high-end manufacturing needs.

Why EDM Machines Are Uniquely Valuable

Electrical Discharge Machining (EDM) is a non-traditional machining process that uses electrical discharges (sparks) to erode conductive materials, enabling the creation of complex shapes, cavities, and fine features without requiring physical cutting contact.

This characteristic makes EDM especially suitable for:

-

Machining very hard, heat-resistant materials (e.g. tool steels, superalloys, titanium) that are difficult or impossible to shape with conventional milling or drilling.

-

Producing intricate geometries — deep cavities, sharp internal corners, fine micro-holes — with high dimensional accuracy and minimal mechanical stress.

-

Achieving high surface finish quality, often eliminating the need for extensive post-processing or heat treatment.

Because of these advantages, EDM has become indispensable across several advanced manufacturing sectors.

Mold and Die Making — Precision Tooling with Intricate Cavities

One of the oldest and most widespread uses of EDM is in tool, die, and mold manufacturing. EDM is particularly well-suited for producing injection-molding dies, stamping dies, die-casting molds, and forging tooling.

-

EDM enables the creation of complex mold cavities with intricate internal geometries, deep ribs, undercuts, and fine features — shapes that are extremely challenging or impossible with conventional machining.

-

The process handles hardened tool steels (even after heat treatment) without deforming them, preserving dimensional accuracy — a critical advantage for long-lasting molds and dies.

-

For toolmakers and mold shops using high-quality EDM machines from Zhiquan, the result is durable, precise, and finely detailed molds and dies, reducing post-processing and ensuring reliable, repeatable production.

This makes EDM a cornerstone technology for industries relying on plastic injection molding, metal stamping, die casting, and related tooling.

Aerospace Manufacturing — Machining Hard Alloys and Complex Components

The aerospace industry is among the most demanding sectors for manufacturing. Components often use heat-resistant superalloys, have intricate geometries, and require extremely tight tolerances. Here, EDM shines.

-

EDM is used to machine turbine blades, impellers, and engine parts made from superalloys (e.g. nickel-based alloys, titanium), which hold up under high temperatures and stresses.

-

The process can create complex internal cooling channels, micro-holes, or intricate cavity structures on parts — features often crucial for performance and safety in jet engines, turbines, or structural components.

-

Because EDM induces no mechanical stress or deformation, it preserves the material’s integrity — essential for critical aerospace parts where reliability matters most.

For aerospace manufacturers using EDM machines from a dependable provider like Zhiquan, this means consistently producing highly complex, high-strength components that meet rigorous tolerances and performance standards.

Medical, Electronics and Micro-Component Manufacturing — High Precision, Small Scale

Beyond mold and aerospace, EDM finds widespread use in industries that demand extreme precision, fine detail, and often small-scale components.

-

In the medical and medical-device industry, EDM machines are used to manufacture surgical instruments, implants, and micro-structured parts from biocompatible or hardened materials while maintaining tight dimensional control.

-

In electronics and semiconductor manufacturing, EDM enables micro-machining of tiny connectors, fine geometries, electrode contacts, and miniature die components — tasks where conventional machining would struggle.

-

For prototyping and custom parts, EDM offers flexibility: rapid turnaround on small-batch jobs, ability to machine complex shapes with minimal setup, and capability to work with exotic conductive materials.

Thanks to the precision, material versatility, and minimal mechanical stress of EDM, manufacturers across medical, electronics, and R&D sectors can rely on EDM machines — including those built by Zhiquan — for high-quality, consistently accurate micro-components.

Research, Energy, and Specialized Industrial Applications

EDM’s reach goes beyond conventional manufacturing: it is also used in research, energy, and highly specialized industrial contexts.

-

In energy and power generation, EDM can machine complex components for turbine systems, flow control parts, or high-precision valves — often made of hard, heat-resistant alloys.

-

For prototyping and R&D work, EDM enables production of intricate test pieces or tooling, especially when working with exotic metals or needing extremely fine tolerances.

-

In niche industries like jewelry, coinage die making, and stamping for decorative or precision items, EDM is used to craft complex dies and molds for stamping or forging.

These applications demonstrate the breadth of EDM’s utility: from large-scale industrial to small-batch specialized work, EDM remains a go-to technology whenever complexity, precision, and material difficulty arise.

Why EDM from Suzhou Zhiquan Electromechanical Equipment Co., Ltd. Stands Out

Choosing EDM machines from a reputable provider such as Suzhou Zhiquan Electromechanical Equipment Co., Ltd. brings specific advantages:

-

Their EDM units are engineered for high-stability, repeatable precision, ideal for molding, aerospace, and medical-grade applications.

-

The machines can handle tough, heat-resistant alloys and tool steels, enabling users to work with superalloys, hardened steels, and other difficult-to-machine materials.

-

With careful design and reliable control systems, Zhiquan’s EDM machines support complex geometries, deep cavities, micro-holes, and fine surface finishes, making them suitable for a wide array of industries and part types.

For manufacturers needing versatility — from heavy-duty molds to delicate medical parts — Zhiquan’s EDM solutions represent a strategic investment in long-term productivity, quality, and adaptability.

Conclusion

EDM machines have become indispensable across modern manufacturing — from precision mold and die making to aerospace components, medical devices, electronics, energy systems, and custom prototyping. Thanks to EDM’s unique ability to machine hard, conductive materials, produce intricate shapes, and maintain tight tolerances without mechanical stress, it continues to enable innovation and quality in industries where traditional machining falls short.

With a proven and professional supplier like Suzhou Zhiquan Electromechanical Equipment Co., Ltd., manufacturers and engineers can confidently leverage EDM to meet complex production challenges, maintain high precision, and deliver superior part quality.

Whether you’re producing complex injection molds, aerospace turbine parts, micro medical components, or custom tooling — EDM remains one of the most versatile and powerful machining technologies available today.

Why Choose a Mirror Spark EDM Machine for Precision Applications?

www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd.